- Low latency, scalable dedicated AI accelerator

- MCU supports real-time motor control

- ROS2 with DDS enables timely communication and interoperability

Application Cases of Cleaning Robots

High performance low power industry controller

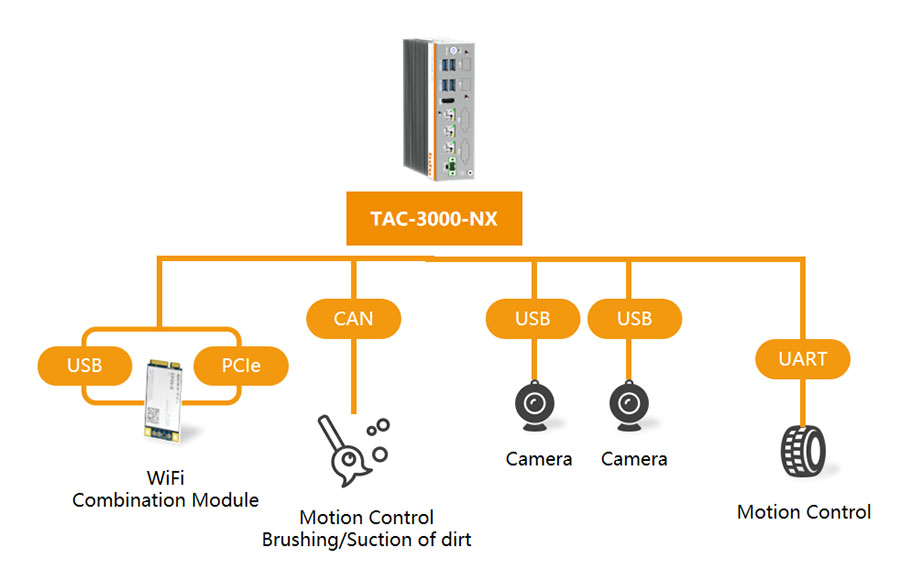

TAC-3000-NX

- Support NVIDIA ® JetsonTM SO-DIMM connector core board

- High performance AI controller with up to 100TOPS computing power

5G LTE

- TDD LTE/FDD LTE/WCDMA/GPS

- Support Region: Global

Ready to use standard systems: rapid construction and expansion

- Production board facilitates sample development and large-scale deployment

- Up to 100 TOPS (INT8) of computing power

- Supports JetPackTM 5.1 SDK

Small size to adapt to narrow spaces

- Easily deploy products to various application scenarios without sacrificing space

- Adopting modular heat dissipation design to adapt to a unified quasi system design

Scalable I/O design to meet different application requirements

- M.2 extensions for initiating and wireless connections: M key for NVMe and B key for wireless applications

- Connect edge devices and peripheral devices through USB, RS-485, GPIO, CAN, and LAN

Application Cases of Cleaning Robots

Application challenges

- Ensure stable and uninterrupted operation of the cleaning robot

- Optimize the battery life plan to ensure a single 6-hour battery life

- Ensure safety and prompt response of cleaning robots to obstacles

Solution

- Drawing, data recording, storage, and real-time monitoring through wireless connection

- Low power consumption, improving charging efficiency each time

- 2 USB industrial camera inputs and up to 100TOPS native AI inference performance, assisting in real-time response

Advantages of the plan

- High cost-effectiveness, easy to promote, stable digital 3D map data, and easy to transmit

- OTA updates to assist in large-scale management of firmware/applications/operating systems/security patches

- The cleaning robot performs consistently and can track equipment conditions through digital records